Individuals and businesses alike are becoming increasingly interested in the Metaverse and related sectors as they continue to develop. Everyone is curious about the Metaverse and how it will affect our future industries and lifestyles.

Smart Manufacturing Galvanizes Ecosystem Formation

The creation of the Metaverse has further enhanced the integration of human intelligence and AI and generated human-centric industry models. Take the manufacturing industry for example, the new combination improves decision-making capabilities and increases the efficiency and flexibility of production and other areas. And these transformations are in line with the future trends of agile governance.

In fact, an increasing number of manufacturers are becoming aware of the concept of Industry 4.0 and gradually introducing technologies such as human-robot collaboration (HRC) into their factories. Recently, people are talking about the Industrial Metaverse which emphasizes human-centric sustainability and flexibility when meeting related industry demands.

The Industrial Metaverse is a concept that combines the virtual and real worlds. The Industrial Metaverse, which is based on IoT, AI, and machine learning technologies, can informatize, digitize, and intelligentize products, equipment, and machinery in the manufacturing and logistics industries, and build a brand-new industry system via online collaborations. The Industrial Metaverse utilizes digitization and intelligentization to increase manufacturing production efficiency and realize intelligent manufacturing and also highlights the importance of data sharing and cross-domain collaborations.

The Industrial Metaverse is considered an upgraded version of the Industrial IoT and can help resolve current pressing issues. For example, it is difficult to effectively conduct data exchange and integration between various underlying communication and data exchange protocols involved in the production lines. After using a large number of sensors and smart devices to collect data, the Industrial Metaverse will utilize blockchain and relevant technologies to satisfy the data and information-sharing needs within the industry.

Realizing the Concept of Industrial Metaverse

Founded in 1954, Yeong Chin Machinery Industries Co. (YCM) has accumulated nearly 70 years’ worth of professional machine tool manufacturing technologies. The company produces professional machine tools with high rigidity and stability. YCM is one of the machine tool manufacturers in Taiwan that has its own casting factory and thus can complete all steps - from casting, machinery processing, equipment assembling, inspection, to packaging and shipment - on the integrated production lines of their factory.

YCM continues to develop smart factory software to upgrade equipment with smart functions. Examples include optimizing equipment performance, extending cutter lifespan, and enhancing equipment maintenance prediction. Leveraging the company’s near-70 years of experience in professional machine tool R&D and production, YCM and leading industrial PC manufacturer Advantech co-founded the business Dot Zero, which focuses on smart manufacturing/IIoT SI.

In the last three years, front-line technicians were unable to freely travel due to the pandemic and this led to delays in equipment refurbishment and replacement as well as processing application maintenance and repairs. This challenge galvanized the development of technologies relevant to remote collaboration and creating digital twin.

Remote collaboration refers to using tablets, mobile phones, or PCs to let workers and/or clients at different locations view real-time images, generate graphics, and execute commands simultaneously. The technology also brings about business process innovations and accelerates digital transformation, as shown in photo 1.

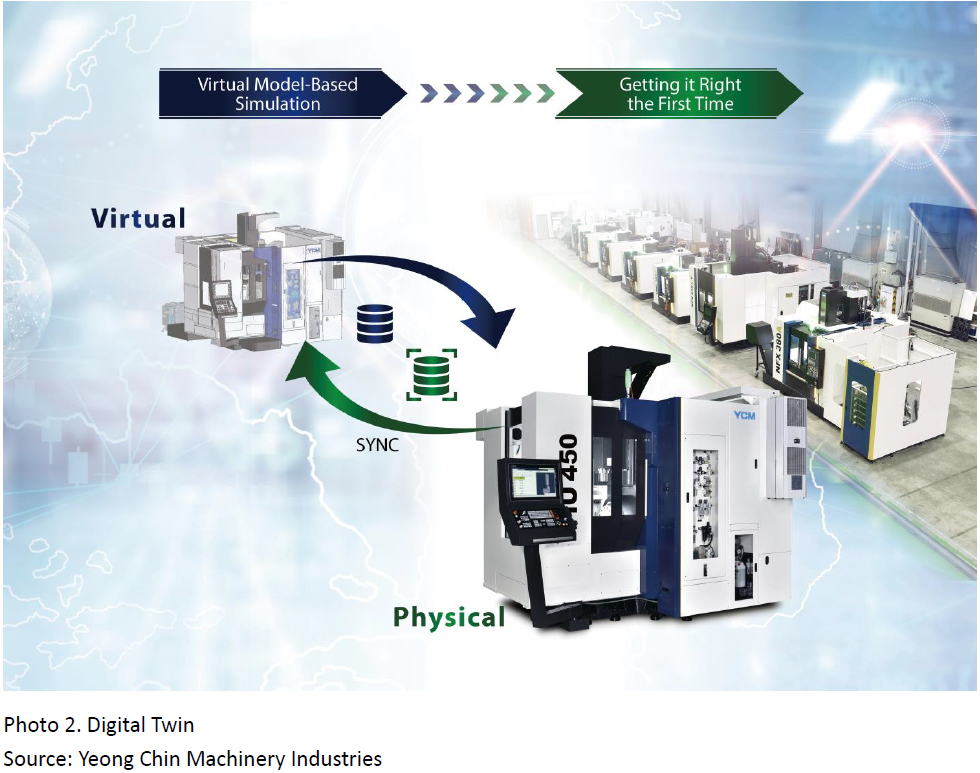

Digital twin can be applied to production line design and equipment production. For instance, converting CAD and BIM files to achieve cyber-physical integration and speed up collaborations regarding new product designs, as shown in photo 2.

Photo 1. Remote collaboration

Photo 2. Digital twin

YCM paired HoloLens 2 with Dynamics 365 Remote Assist to carry out remote staff training as well as the installation, maintenance, and inspection of client equipment. With the HoloLens 2 interactive holographic projections, technicians at the client end can directly see the technical data and drawings shared by Yeong Chin Machinery via helmet-mounted displays (HMD). The HoloLens 2 Mixed Reality device coupled with Dynamics 365 Remote Assist allows collaborations via Microsoft Teams, therefore on-site and remote personnel can choose to communicate via con-call or Teams meetings.

Accelerating Ecosystem Development and Landing

ITRI is working on relevant technology R&D in line with the trends of smart manufacturing and the Industrial Metaverse as the institute regularly gathers insights on business needs and technology application requirements of the industry to create synergy for industry development. Applications include developing innovative Industrial Metaverse technologies, assisting in domestic Industrial Metaverse technical upgrading, and boosting the production value of pertinent industries by 10%. ITRI also completed a localization Industrial Metaverse cloud service platform to encourage businesses to prioritize smart manufacturing industries (textile, shoe, metal processing) and thereby improve domestic production quality and reduce product carbon emissions. Other contributions include helping machine tool factories set up remote collaboration diagnostic systems, which is expected to reduce 30% of aftersales service costs and create a brand-new service model; and assisting the manufacturing industry in setting up plant-wide digital twin and remote collaboration process diagnostic systems. The latter system can save half of the production line establishment time and reduce 50% of process craft transfer costs.

Amidst the diverse and rapidly changing waves of emerging technologies, ITRI’s solution is to follow its 2035 Technology Strategy & Roadmap and continue to invest in relevant R&D, such as developing factory IoT platforms, cloud manufacturing, and quality management systems. The goal is to use technology innovation to transform lives and develop solutions led by market demands.

ITRI strives to further advance the development of smart manufacturing and Industrial Metaverse technologies (e.g. machine learning, IoT, big data). In addition to integrating various resources to develop new types of soft/hardware products, the institute continues to promote the application of smart manufacturing and galvanize automation, digitization, and intelligentization in different industries.